10 Amazing products that can be produced 100% sustainably with carbon neutral biopolymers

Did you know that there is already a technology that can replace oil as a raw material for many everyday products?

The ever-growing demand for environmentally friendlier options is shaping the production of daily consumables worldwide. The chemical industry is almost entirely dependent on petroleum. Everyday products, from plastics, cosmetics and paints to adhesives and drugs are often made from oil. However, global challenges such as climate change and plastic pollution are now shifting the focus towards renewable and biodegradable raw materials – like our carbon neutral biopolymers.

CH-Bioforce’s technology fractionates all biomass main components in one process. The resulting carbon neutral biopolymers – cellulose, polymeric hemicellulose, and sulphur-free lignin – are all extremely pure. These high-quality raw materials enable our partners to produce environmentally friendly products in a number of industries. The beachhead market for our cellulose is the textile industry, which is a global and mature market keenly looking for ways to improve its sustainability. The most important markets for polymeric hemicellulose and sulphur-free lignin are in bio-based chemicals and bio-based plastics.

The future is already here, and here are ten examples of amazing things that can be done with our revolutionary technology – all replacing the need for oil- and food-based raw materials in a 100% sustainable way!

1. High-quality textiles and clothing

CH-Bioforce’s high-purity cellulose can be refined into textiles. The end product could be a T-shirt, towel or a shopping bag. The technology is already in place and fully functional. In our high-quality cellulose the fibres are intact, with no signs of peeling, and they are easy to bleach and fibrillate. It can be used in applications that require a high chemical purity and a particularly low hemicellulose content – for example in textiles replacing cotton.

2. Paints

One highly promising area of application for hemicelluloses is found in paints. Today, the paint industry uses synthetic and oil-based materials as stabilizers. These can, however, be toxic and harmful to the environment. Past research has shown that hemicelluloses are a very promising biomaterial that could be used in their place.

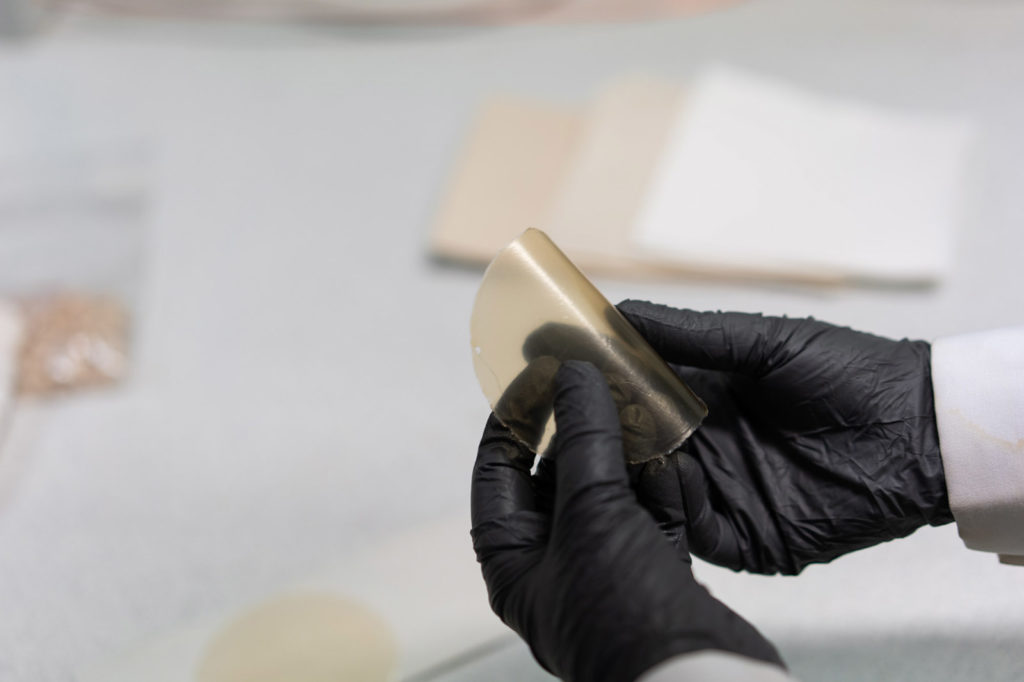

3. Plastic

Lignin can be turned into plastic for injection moulding. Imagine all the possibilities! Everyday objects like kitchen utensils or toys can be produced 100% sustainably instead of from oil or food-based materials.

4. Bio-based Cosmetics

Did you know that many cosmetic products require an emulsifier to achieve the right consistency? Without it your hand cream or makeup remover would not function at all. An attractive market segment for hemicellulose is as an emulsifier in cosmetics industry. Emulsifiers are used practically in all cosmetics products to mix water with oil. Additionally, lignin is used in cosmetics for its sun-blocking abilities.

5. Detergents

One of the main markets for polymeric hemicellulose and sulphur-free lignin is in bio-based chemicals. They can be used to manufacture environmentally friendly and very effective detergents.

6. Packaging

We provide the only technology in the world, which can produce hemicellulose in its natural, polymeric form. Due to its water solubility, biodegradability and amorphous, flexible structure, polymeric hemicellulose can be used feasibly in paper and board coatings replacing oil and starch.

7. Pharmaceuticals

Due its extraordinary properties, our cellulose can be refined into Micro-fibrillated Cellulose (MFC) with a reasonable cost. MFC can be used in medical applications, such as pharmaceutical fillers.

8. Food industry

High purity cellulose has an existing market in food industry. In addition to cosmetics emulsifier and detergents, our hemicellulose has been evaluated as a dietary fibre and emulsifier in food applications.

9. Glue

We have been able to manufacture environmentally friendly glue from several biomass feedstock such as straw, wood, and even brewers spent grain (BSG).

10. Energy and fuel

Lignin is one option to replace graphite in battery industry. Lignin can be pressed into high-energy pellets and used as fuel in energy plants. Compared to fossil petroleum, lignin derived from wood or even straw, for example, offers a more climate-friendly way for energy production.

Join us on our journey – let’s work together!

Follow us for latest news!

Twitter @CHBioforce

LinkedIn CH-Bioforce Oy

YouTube CH-Bioforce Oy

Why should I choose CH-Bioforce as a partner? Five benefits of BIOFORSENSE® technology

What makes us unique and why should we work together for a more sustainable future? Here are five benefits of the BIOFORSENSE® technology.

» Read more

It’s all about sustainability – three ways BIOFORSENSE® technology can save valuable resources

Renewable raw materials for sustainable living – this is how our customers gain a unique market position as providers of sustainable and bio-based products.

» Read more

10 Amazing products that can be produced 100% sustainably with carbon neutral biopolymers

Did you know that there is a technology that can convert biomass into raw materials to replace both fossil- and food-based raw materials in many everyday products?

» Read more

A World Without Waste – ABC of Utilizing Industrial Production Side Streams

Our seas, rivers, and lakes are full of microplastics, and the mass production of various consumer products destroys our beloved, pure nature, a source of refreshment and recreation. This needs to be changed.

» Read more

CH-Bioforce Oy

CH-Bioforce Oy is a Finnish start-up founded in 2016. The company’s innovative BIOFORSENSE® biomass fractionation technology dates back to 2011, when inventors Lari Vähäsalo, Nicholas Lax and Sebastian von Schoultz made their first findings. Today, the company forms part of the Chemec group, which operates in the chemical industry. CH-Bioforce currently employs ten members of staff. Our R&D and pilot plant is located in Raisio, Finland.

For more information

Mari Taipale

Director, CH-Bioforce Oy